机器优势Advantages

多次压套,提高产品质量。Repeatedly cap press, improve product quality.

可视化简易触控操作系统。Visual summary touch summary.

光纤检测空针,自动定位上护套。Optical fiber detection of empty needle, automatic positioning of upper sheath.

精密伺服系统,平衡均匀迅速点胶工艺。Precision servo system, balanced and rapid dispensing process.

CCD在线检测毛刺、倒针、空针,提高产品质量。CCD online checking the inversion needle/empty needle.

产品质量设有光纤计数功能,避免人工清点。Equipped with counting alarm to avoid manual counting.

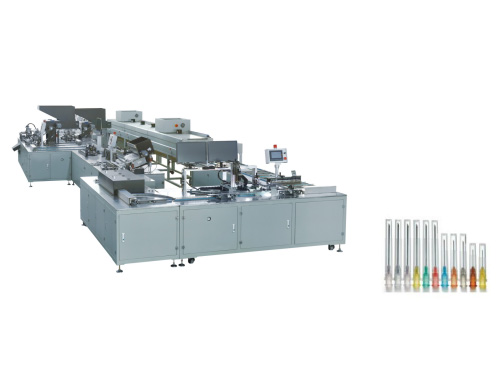

工作流程 Assembling process

上针座→上针→上胶→压针→烘干→检堵→CCD检测毛刺倒针→硅化→剔废→上护套→二次压护套→下料

Hub feeding→Cannula feeding→Gluing→Needle Pressing→Drying→Blockage Detection→Siliconization→ Auto reject→ Cap feeding→Twice cap pressing→Discharging

设备配置 Configurations

PLC: 欧姆龙OMRON 伺服电机 servo system: 松下 Panasonic 触控界面 Touch screen:科步Kinco

气动元件 Pneumatic component: SMC 视觉系统 Camera system: 基恩士 KEYENCE 光纤系统 Optical systems: 基恩士KEYENCE

技术参数Technical parameters

|

生产能力(支/时)Capacity |

70,000pcs per hour (for master) |

|

操作人员(人)Operation of worker |

1 inspectors |

|

空气压力Air pressure |

≥0.60Mpa |

|

空气流量(毫升/分)Airflow |

≥300ml/min |

|

功率(Kw)Power supply |

380V * 50Hz*15Kw*3P+N+PE |

|

8Kw for Normal working time |

|

|

14Kw for working after half an hour |

|

|

机器尺寸(长*宽*高)Dimension |

7m(L)*3.4m(W)*1.6m(H) |

|

重量Weight: |

3000kg |

拨打13850118259

拨打13850118259

拨打13850118259