SMARTELL TECHNOLOGY CO., LTD. is professional in the production and development of syringes and infusion set production molds, machines and other necessary equipment. As a turnkey solution supplier,we have the whole syringe machine production line includes Syringe Barrel Printing Machine, Syringe Assembly Machine,Infusion Set Assembly Machine,Syringe&Infusion Set Packing Machine and so on.

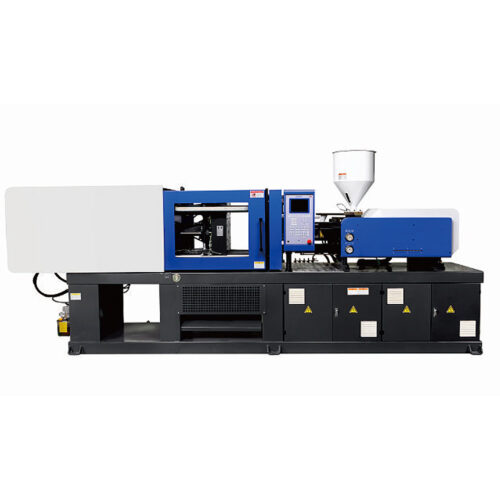

The plastic injection molding machine is to produce the plastic parts of the disposable syringe and infusion set by working together with the customized mold and some auxiliary equipment. Injection molding machines are the injection and clamping sections. Plastic injection molding equipment consists of the plasticizing system, injection system, clamping system, and transmission system. In order to improve the stability of syringe production, it is necessary to add the infrared heating coil to the standard injection molding machine. In addition, Adding the servo motor system is also recommended, although the servo motor will increase the cost of the injection molding machine, the servo motor system has the advantages of energy saving, in long term production, it is more economic, so nowadays more and more companies choose servo motor system. The workshop will be equipped with a crane to position the mold. The injection molding machine is 80 cm away from the wall. The injection workshop is at a high temperature during the production process because machines generate a lot of heat. So when the injection molding workshop is constructed, it is necessary to fully consider the ventilation problems in the workshop. The height of the workshop building must have a certain space, preferably more than 4 meters.

Please feel free to click here if you have any questions about smartell Syringe machine production line.